Machining

Ever since the foundation of our company in 1969 and to this day, we have been faithful to our philosophy of "precise and cost-effective manufacturing". In 1978 we added a CNC controlled machining production to our traditional toolmaking and mechanical engineering. Significant value is placed on our production facilities always being at the cutting edge of technology.

With CNC machining centers and latest CAD-CAM systems we produce turned and milled parts of the highest quality from batches of 100 pieces. Our work material is anything that may be machined: steel, stainless steel, aluminum, brass, plastic, castings and forgings.

CNC milling

We manufacture individually and flexibly on latest generation machining centers, making use of state-of-the-art tool technology and decades of experience.

In addition to using latest tooling machines, highly qualified staff are the foundation stone when it comes to producing technical drawings of perfect quality. Continual training ensures this know-how is constantly developed further.

CNC turning

Our lathes with driven tools are ideally suited for combined turning and milling operations. All machines are equipped with a counter-spindle, enabling final processing in just one step.

Our contour measuring instrument ensures the dimension integrity of complex turning geometries, thereby facilitating micrometer-precise enlargements of critical bevels and radii.

Special machinery

Large volumes of up to 500,000 pcs per year are produced on rotary transfer machines equipped with robots. Based on this automation and parallel to machining further processes are run:

Quality assurance

To us quality is the result of carefully considered and well-functioning business processes that start with the first customer contact and go right through to delivery and after-sales service. While our company is certified in accordance with ISO 9001:2015, upon your request we will be glad to carry out further Q-methods for you such as SPC, FMEA or Ishikawa.

Additional processing

Besides machining we will be glad to carry out further operations for you.

Internal additional processing

External through certified partners

“…because we love what we do.

Ever since the company’s foundation in 1969 we have been manufacturing with modern CNC machining centers, precisely and economically.

Robert Gröninger

References

The turned and milled parts shown here are representative of our performance ability and know-how in machining.

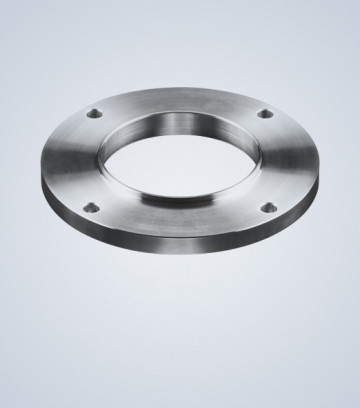

Flanges for the food industry

Combined turning and milling operations | High surface quality | High dimension integrity of contours

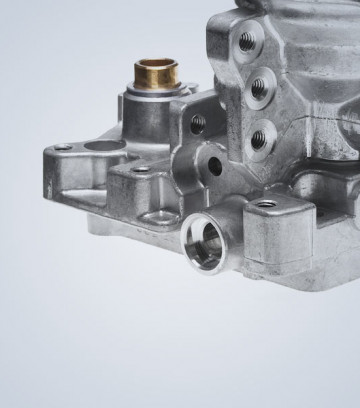

Aluminium housing for diesel pumps

Rotary transfer machines | Large quantities form 2,000 pcs per day | Wide variety | 0ppm goal achieved!

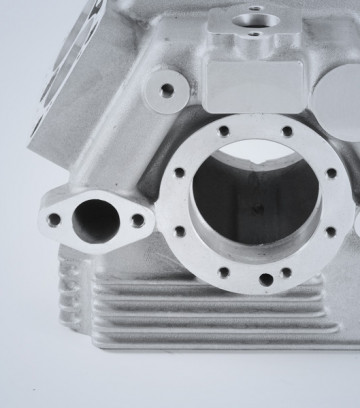

Cast and forging parts for the automotive industry

Combined turning and milling operations | Automated workpiece handling | Honing

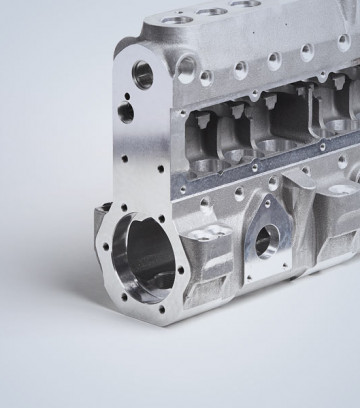

Lathed and milled parts for special machine industry

Our work material: anything that may be machined!

Injection pumps

Edge length 600mm | Small shape and position tolerances | Wide variety | Deep-hole boring

Gröninger Machining

In the video portrait on Youtube

Our machines

Find out more about our machines

Quality

Our certificate from Quacert for quality management

Environment

Our certificate from Quacert for environmental management